Posted on 22nd November 2022

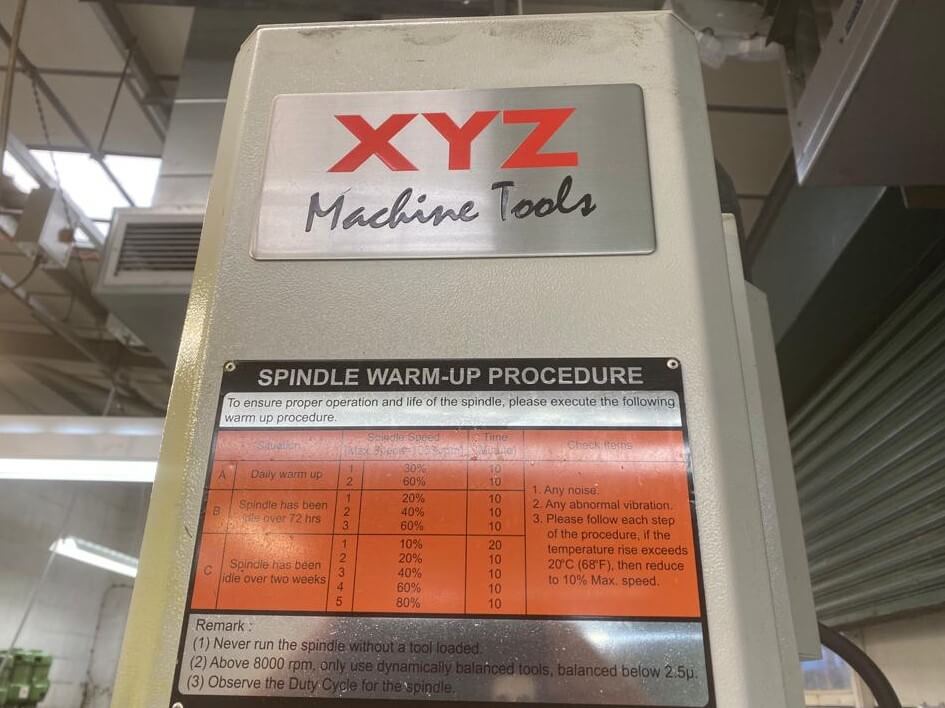

Siemens 810D is a great control which we provide a lot of support for and are commonly used across many machine tools, XYZ being the most popular. A common issue on them is the failure of CCU3 / CCU3.4. Over time, dirt and coolant ingress causes component failure on the PCB rendering your machine inoperable. We now have a cost effective fix for these failures for both CCU3 (6FC5410-0AY03-0AA1, 6FC5410-0AY03-0AA0) and CCU3.4 (6FC5410-0AY03-1AA0).

Posted on 2nd May 2022

Saved our customer ££££’s with the repair on this Sinumerik 810D HMI screen. We were able to fully repair with spare parts we keep in stock meaning a mega quick turnaround for a fraction of the price of replacement.

Posted on 3rd January 2022

After diagnosis we found the spindle motor to be dead short across all three phases which is worrying considering it had been “rebuilt” around 12 months ago by a well known repair company!

Posted on 26th November 2021

After diagnosis we found the spindle motor to be dead short across all three phases which is worrying considering it had been “rebuilt” around 12 months ago by a well known repair company!

Posted on 10th November 2021

Recently we had an urgent enquiry from a new customer in the North East. The spindle on their Breton NC260 had failed during one of their busiest periods.

Posted on 11th September 2021

This is a fault we see quite regularly on Siemens 828D and 840DSL systems, multiple drive errors including cyclic data transfer alarms and over-temperature alarms.

Posted on 10th September 2021

Two machines currently for sale, based in Kidderminster, an XYZ Minimill 560 VMC CNC Machining centre and a XYZ Vulcan 150 TC. 2002 Model year.

Posted on 6th June 2021

A small job that turned into a complete overhaul! This 12 year old XYZ 1060HS VMC had ground to a halt with multiple X axis drive alarms.

Posted on 5th June 2021

This was a nice straightforward job, we replaced the spindle in a Kitamura horizontal machining centre in the North East of England.

Posted on 5th April 2021

XYZ 1060 VMC with a bit of an unusual fault. It initially started out with a Z axis brake fault, when the emergency stop was engaged the head fell under gravity and hit the dead stop.

Posted on 19th February 2021

Today we retro-fitted a 4th axis to a Dugard Eco 1000 VMC with Siemens 828D control and Sinamics drives. This was not a straightforward task, this machine had never had a 4th axis and had absolutely no interface preparation whatsoever.

Posted on 8th February 2021

Our customer was considering scrapping this 21 year old XYZ Vulcan with Siemens 810D control when the CCU1 failed to boot after being turned off for a long period of time.

Posted on 6th February 2021

We had a nice straightforward install on this Hurco TM8i with barfeed.

Posted on 27th January 2021

This is a 4th axis cable built to interface a Detron Rotary table with Heidenhain motor onto a Dugard VMC1000 with Siemens 828D control.

Posted on 15th January 2021

It has been a busy post holiday return to work with lots of slightly older machines struggling to function after a few weeks off! This is always the case over Christmas and New Year.

This Hardinge VMC1000ii with Sinumerik drives and 810D control unfortunately suffered from a blown 50A drive. This is a common failure on CCU boxes, it always seems to be the 50A (spindle) port that blows.

Posted on 13th November 2020

One of our jobs this week, kit one of our customers out with coolant mist extraction units.

2 down, 14 more to go!

Posted on 6th October 2020

So happy to see a green run LED on this PLC on a customer’s wash plant after seeing a red SF LED for the last few hours.

This VIPA PLC looks like a Siemens CPU, acts like a Siemens PLC and even works with Siemens S7 software however it isn’t!

Posted on 27th August 2020

Coolant ingress over time washed the grease out of the bearings on this spindle, causing them to heat up, dry out and eventually fail.

Posted on 20th August 2020

This is an XYZ TC250 with a noisy spindle, finally after 14 years of turning the same job day in and day out the bearings have finally dried up and worn out!

Posted on 5th August 2020

The X axis was immediately tripping out on this 1998 Bridgeport VMC800 when trying to reference, we were called in as the customer suspected the faults were caused by a faulty servo drive or servo motor.

Posted on 23rd July 2020

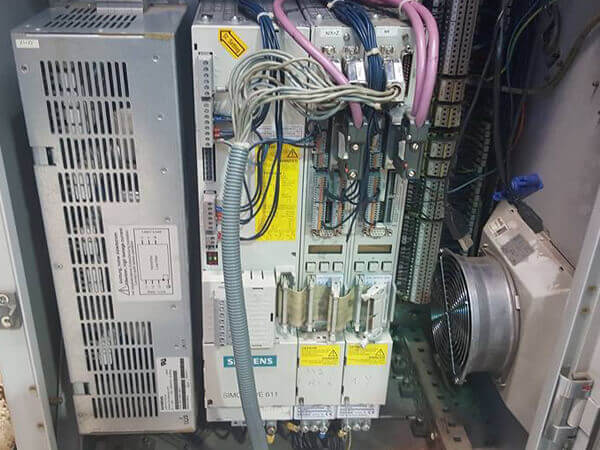

A common failure on Siemens and Heidenhain Controlled CNC machines such as XYZ, Hardinge, Bridgeport, Breton, Dugard is E/R module failure.

The most common failure type we see is the 16/21 KW (6SN1145-1BA01-0BA1(2/0).

Posted on 8th July 2020

I installed this fantastic used Dugard ECO 1000 VMC today with Siemens 828D Control and Sinamics drives.

Posted on 7th July 2020

It can often be a struggle getting a tool setter to calibrate correctly and we have a lot of customers contacting us for assistance with this.

Posted on 24th June 2020

This is a fantastic used XYZ 250TC Live Tooling sold and installed in it’s new home.

Posted on 5th June 2020

A chance occurrence caused the PLC in the 1.5 year old Doosan DNM 5700 VMC with Siemens 828D control to lock up and generate a spurious alarm indicating that the side maintenance doors were open, even though they weren’t and no input signals from the door sensors were missing.

Posted on 22nd May 2020

VIDEO This was a frustrating issue for our customer on his XYZ Vulcan 250. This turning centre was suffering with intermittent turret clamp / unclamp faults which was disrupting production of vital ventilator components.

Posted on 8th April 2020

A noisy spindle and poor surface finish on his Hardinge lathe was the complaint from this customer. We carried out a site visit to diagnose, after a few checks and tests we concluded that the spindle bearings had started to fail.

Posted on 30th March 2020

Some of the earlier Siemens 810D and 840D controls can suffer with hard-drive data loss and data corruption. This is more often than not caused by not shutting them down correctly.

Posted on 9th March 2020

Spindle drive belts are often overlooked as part of routine PM checks.

This Hurco VMX42 suffered drive belt failure purely down to contaminant ingress on the belts, something that could have been avoided.

Posted on 28th February 2020

This was a first for us having never worked on one of these machines before. This is the XYZ UMC 5-X (The Challenger) - 5 axis VMC with Siemens 840Dsl control and Sinamics drives.

Posted on 30th January 2020

This week I have been working on a Takisawa T10 lathe which wouldn’t power up. I was able to quickly diagnose the problem as a faulty hydraulic pump.

Posted on 28th January 2020

It was a pleasure to work on this old girl today, feeling very nostalgic working on this Yang with Acramatic 2100 control.

Posted on 17th January 2020

Working locally today, our customer was complaining of intermittent B axis encoder faults on his XYZ 1060HS with 4th and 5th axis’ and 840DSL control.

Posted on 13th December 2019

Something a bit different from the usual CNC Machining and Turning Centres today...a CNC laser cutter. This Gantry style laser cutting machine suffered a serious malfunction at our customer’s in the West Midlands.

Unfortunately a mechanical jam caused a series of drive failures, 1 regulator card and 2 LT modules (power sections) failed as a result.

Posted on 12th December 2019

Today we’ve been working on the stunning factory fresh Mach 1062 VMC with Siemens 828D control. Firstly we had to configure it for through spindle coolant after fitting an upgraded encapsulated spindle, this involved using HMI Startup with a field PG to update the topology.

Posted on 4th December 2019

A very busy day today replacing a 2x15A drive on an XYZ Minimill 560 with Siemens 802D control after the X axis failed with a drive fault. The next task was to overcome a software glitch on another XYZ, this time a 710VMC with Siemens 828D control.

Posted on 21st November 2019

Siemens 611U fault, alarm E-A608 speed controller output limited.

The fault was diagnosed by swapping the power section (LT module) to another axis and the fault followed indicating a faulty LT module.

Posted on 13th November 2019

This week we have been resolving multiple topology errors on a Dugard Eco VMC with Siemens 828D control and Sinamics drives.

Posted on 3rd November 2019

This week we have been working on a spindle removal and refurb from a 30 year old machine. We found this to be particularly challenging as we had never seen one of these machines before and were following the failed attempts of another machine tool repair company.

Posted on 23rd October 2019

Control CNC are now using ServiceM8 for booking and enquiries, you can book an Engineer or request a quote by clicking on the green "Request Booking" button.

Posted on 6th October 2019

I am over the moon to be sponsoring Stourport Swifts Juniors U10's this season.

Posted on 17th September 2019

This is a common issue that can be hard to diagnose, our customer was experiencing intermittent PLC stop issues that were hindering production.

Posted on 9th September 2019

VIDEO Retrofitting a 4th axis to a 10 year old Hardinge VMC600II that's never had a 4th axis fitted.

Posted on 4th August 2019

A great way of optimizing your machine's performance is regular servicing and alignment checks.

Posted on 26th June 2019

Remove and refit Spindle on a Breton NC260 for our customer in the North East. 380 miles and 13 hours later the machine was back in production and running like a dream.

Posted on 18th March 2019

This is an XYZ TC 200 with driven tooling realignment. The dowels were a bit of a challenge to remove on this one! All realigned and cutting straight again.

Posted on 5th March 2019

There is nothing worse than a dark work area inside your machine. Normal halogen lights tend to suffer from coolant ingress and blow prematurely often taking out the control voltage with it.

Posted on 24th January 2019

Spindle drive belts, such a cheap item to purchase yet so often overlooked. Oil and coolant ingress can often damage them without any knowledge of the user until it's too late and they fail.

Posted on 14th December 2018

Are you ISO 9001 accredited? Would your machine shop pass an audit? We service and inspect all CNC machines satisfying all preventative maintenance stipulations for ISO compliance.

Posted on 4th December 2018

To the casual eye, all can often seem ok however once you start to interrogate electronic repairs under magnification, the true magnitude of botched jobs can easily be seen.

Posted on 26th November 2018

VIDEO Siemens 810D CCU start up procedure from power on to completed boot. A healthy CCU is a number 6, green +5v, green PR and flashing amber CB.

Posted on 26th October 2018

"There's a funny smell coming from the Electrical Cabinet." 50A Spindle drive on Siemens 810D went bang. All three phases failed diode test (No surprise there).

This is a fairly common failure on CCU boxes, specifically on the 50A Spindle drive.

Posted on 14th December 2018

Are you ISO 9001 accredited? Would your machine shop pass an audit? We service and inspect all CNC machines satisfying all preventative maintenance stipulations for ISO compliance.

Posted on 21st August 2018

XYZ CT52 Lathe with Siemens 828DSL & Sinamics drives. A hardware fault of active encoder on Z axis alarm was identified.

Posted on 17th July 2018

VIDEO This 17 year old Hardinge VMC 1000 with Siemens 810D, hasn't struck a blow for 8 years.

Posted on 25th March 2018

One of the mechanical jobs we have completed this week. Our customer complained of poor surface finish when cutting in the X plane on his XYZ 710VMC.

Posted on 16th February 2018

YCM NXV560A with Siemens 828D control with tool change issue. After mains air failure it hung up during toolchange.

Posted on 12th February 2018

Hardinge VMC Mill with Sinumerik 810D, we were able to successfully recommission.

Posted on 27th June 2017

We were recently contacted by a new customer who found us by recommendation from a company we support on a regular basis. This customer based on the south coast had returned to their machine, an Emag VSC 400 Duo with Sinumerik 840D and 611D drives and suffered huge issues.

Posted on 23rd May 2017

CNC Machines are sensitive things often costing several hundred thousand pounds. In order to maximise their lifespan it is important to carry out regular housekeeping and checks.

Posted on 29th April 2017

Many people underestimate the damage that airbourne oil and dirt contamination can do. Pictured here is the root cause failure of a Siemens 16/21 kW E/R module.

Posted on 3rd April 2017

VIDEO We were asked to build a Sinamics Rig for a local repair company to enable them to demonstrate and function test the latest range of Sinamics drives, motors and hardware.

Posted on 24th March 2017

Such a simple little thing yet the consequences of ignoring the battery and fan in your NCU will result in disastrous consequences.

Posted on 22nd February 2017

Today something completely different. A Fanuc (dirty word I know) Robodrill which we were called to after a collision which left the toolchanger out of alignment.

Posted on 7th February 2017

611 heaven! Good old 611 drives, customer had suffered a good bang when the regen failed on his E/R module which consequently took out a 2x25A LT module and power supply.

Posted on 1st February 2017

Refit this little beauty (828D PPU) to XYZ Mini Mill after we carried out a mega fast repair for our customer.

Posted on 25th January 2017

Today we looked at an XYZ Lathe with Siemens 828D control. We were called to assist a customer who after making an edit to one of his programs and trying to run it in simulation, suffered a complete control lockout.

Posted on 20th January 2017

Sometimes new isn't necessarily better. Today a customer brought out his Meger to test a motor, "...it was here when Frank started and he's been here 50 years!" - was the comment from the customer.

Posted on 11th January 2017

We were called to investigate positional discrepancies on the Z axis of a MAG Specht CNC machine.

New encoders were fitted on Z1 and Z2 and positions checked.

Posted on 4th January 2017

Oops! This is what happens when a Deublin valve seizes while the spindle is cutting at 15000 rpm! A bit of mechanical work today, including a new hose built up for us by Pirtek, a replacement Deublin valve and the customer's Mazak Vertical mill is up and running again in no time!

Posted on 7th December 2016

A testing job this week, multiple topology errors on a Hardinge Bridgeport 828D machine, after the drive and cables had been tested and proven and a suspect encoder had been replaced, we were called to assist in the diagnosis of the fault.

Posted on 24th November 2016

Completed 840D Powerline rig with 611D drives capable of running multiple axis'. This rig enables us to diagnose and test multiple Sinumerik hardware including reg boards, LT modules, ER modules, motors encoders and any associated 840D hardware.